-

Galden® D

-

-

Galden® LS/HS

-

-

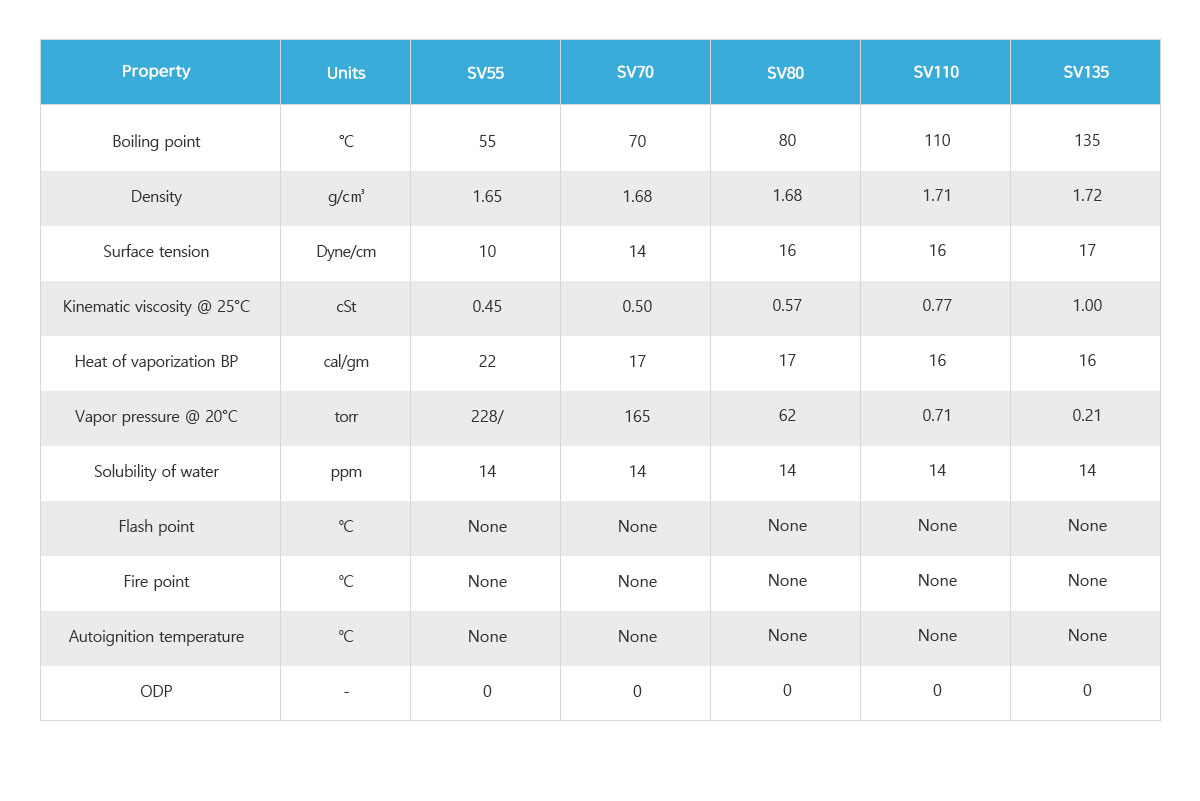

Galden® SV

-

-

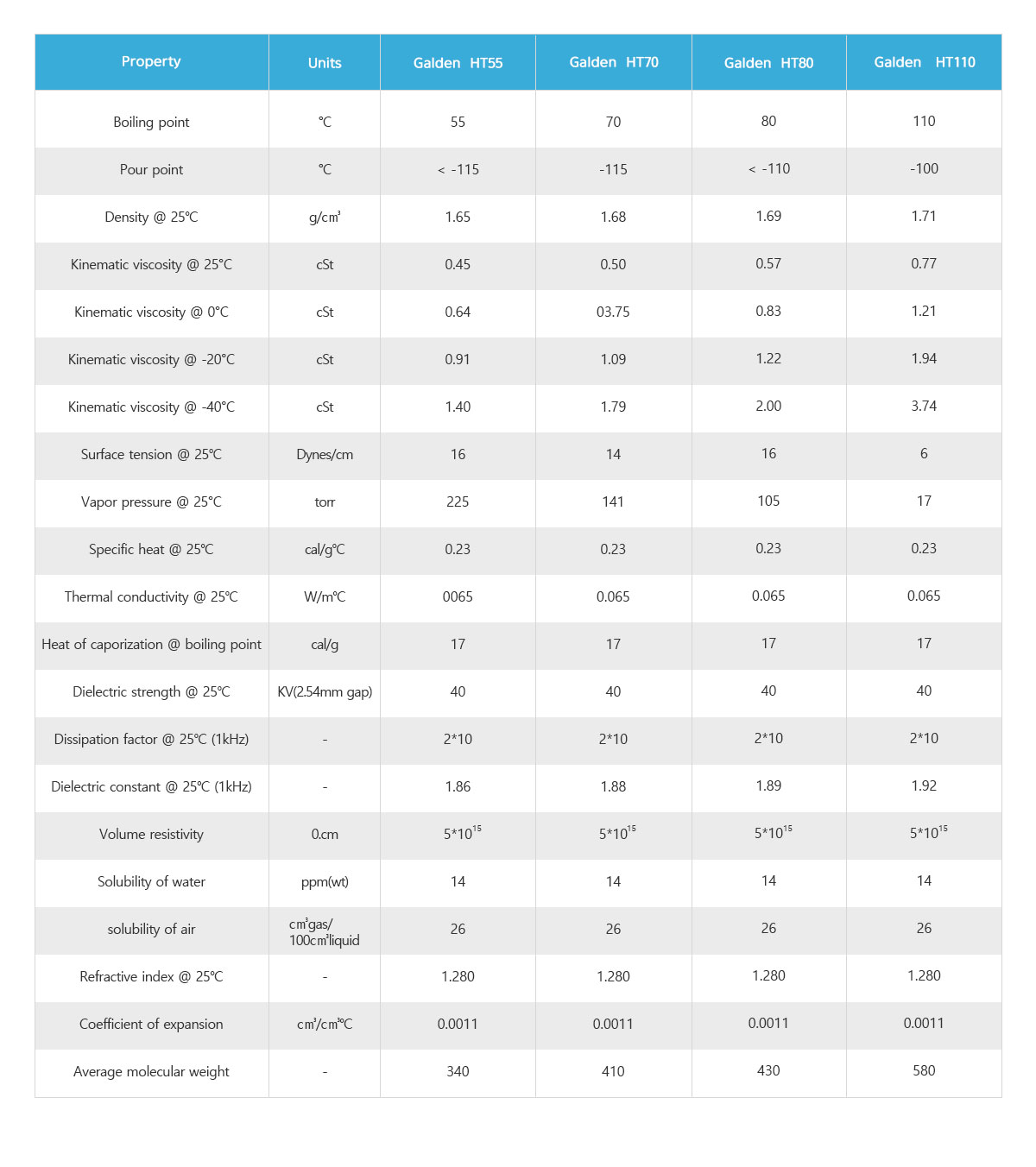

Galden® HT-Low Boilers

-

-

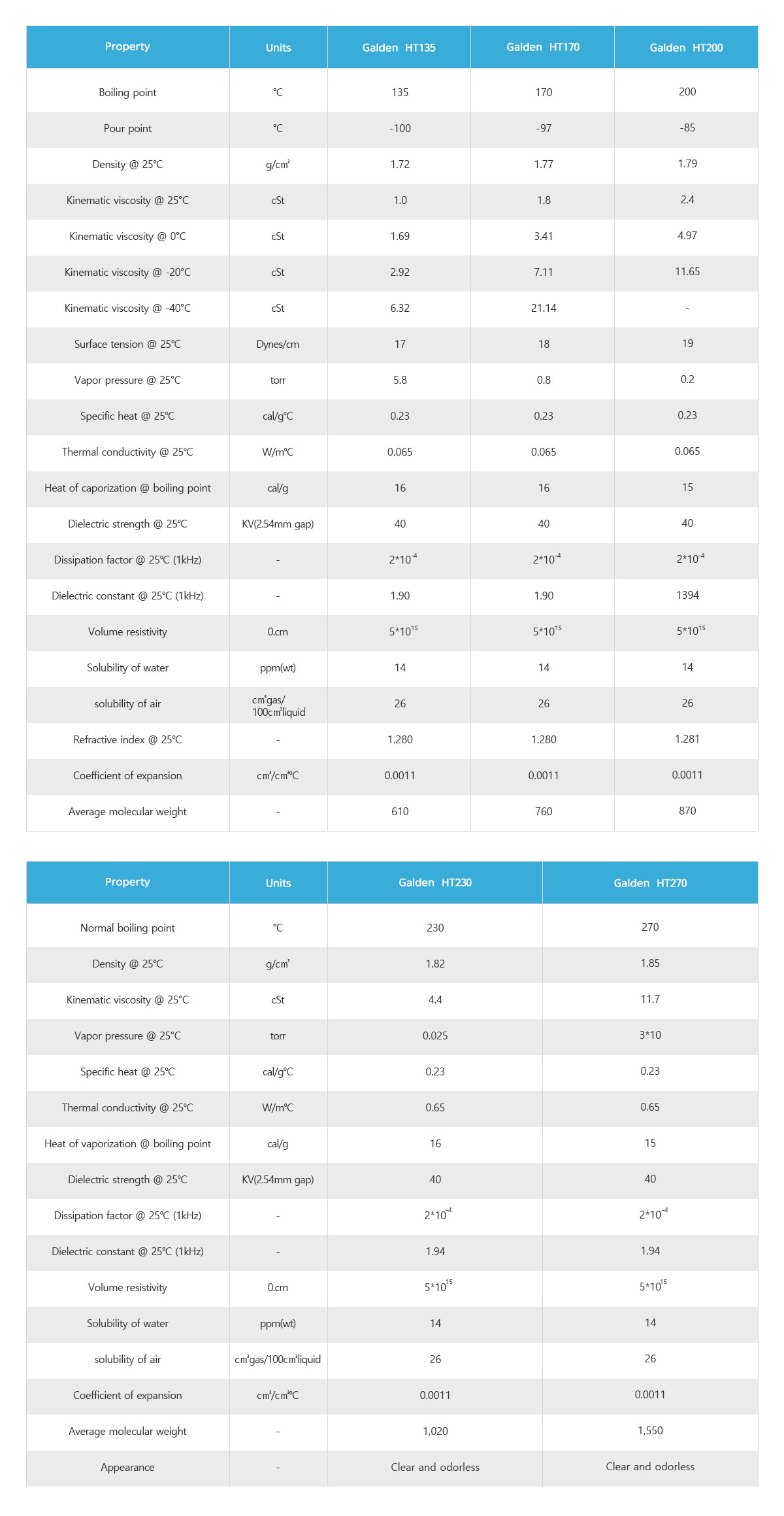

Galden® HT-High Boilers

-

Frequently Asked Questions

-

Galden® PFPE Fluid Properties

-

-

Compatibility Tests

-

-

What Types of Materials IS NOT an Issue?

-

-

Galden® PFPE Fluid Compatibility with Plastics

-

-

How Do I Select a Fluid for a HT Application?

-

-

What is Heat Transfer Factor (HTF) and Pressure Drop (Fρ)?

-

-

How Do I Size a Heater for Use with Galden® PFPE Fluids?

-

-

What is the Difference Between Galden® HT and Galden® LS/HS?

-

-

What is the Difference Between Boiling Point, TRL and TRV?

-

-

How Can I Detect Fluid Leaks?

-

-

Are Galden® PFPE Fluids Food Grade Approved?

-

-

Do Galden® PFPE Fluids Satisfy MIL Requirements?

-

-

What is the shelf life for Galden® PFPE?

-

Applications

-

Heat Transfer Fluids

-

The main purpose of a process cooling fluid is to control or maintain the consta

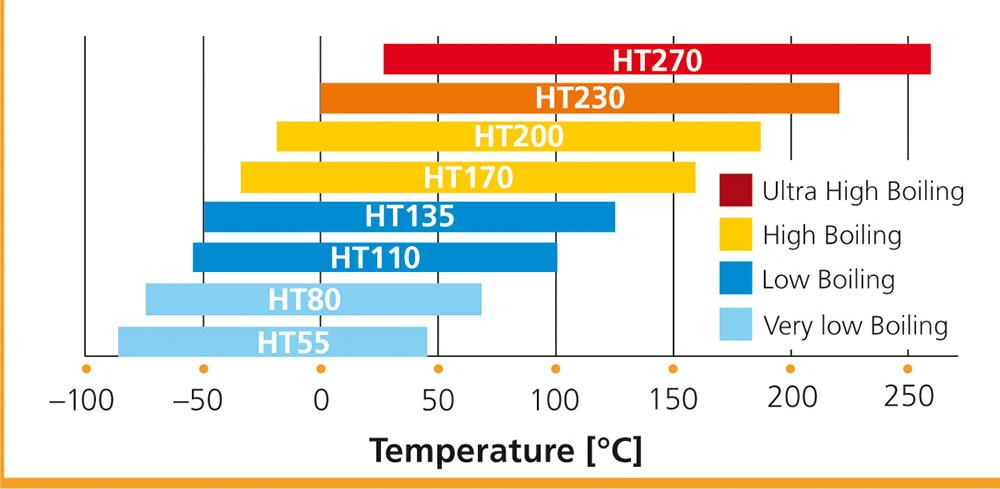

nt temperature of the wafer to a certain set point in order to avoid potential material damage.Galden® PFPE HT is a line of heat transfer fluids with boiling points ranging from 55°C to 270°C. Their excellent dielectric properties, high chemical stability combined with their capacity to operate at very low as well as elevated temperatures make them the best heat transfer fluids for the aggressive conditions used in the Semiconductor and Electronic Industry.

Galden® PFPE HT fluids show excellent compatibility with most of the materials commonly present in heat exchangers. Galden® PFPE systems are practically maintenance-free with no corrosion hazard. Galden® PFPEdielectric properties do not change with use with no risk of short circuiting. Environmentally safe, Galden® PFPE is non-toxic, non-explosive, and will not damage electronics should any leakage occur. No Flash or Fire Point and No Auto-ignition Point are additional advantages of Galden® PFPE HT.

Galden® HT PFPE: operating temperature range

-

Electrical/Electronics Production Equipment

-

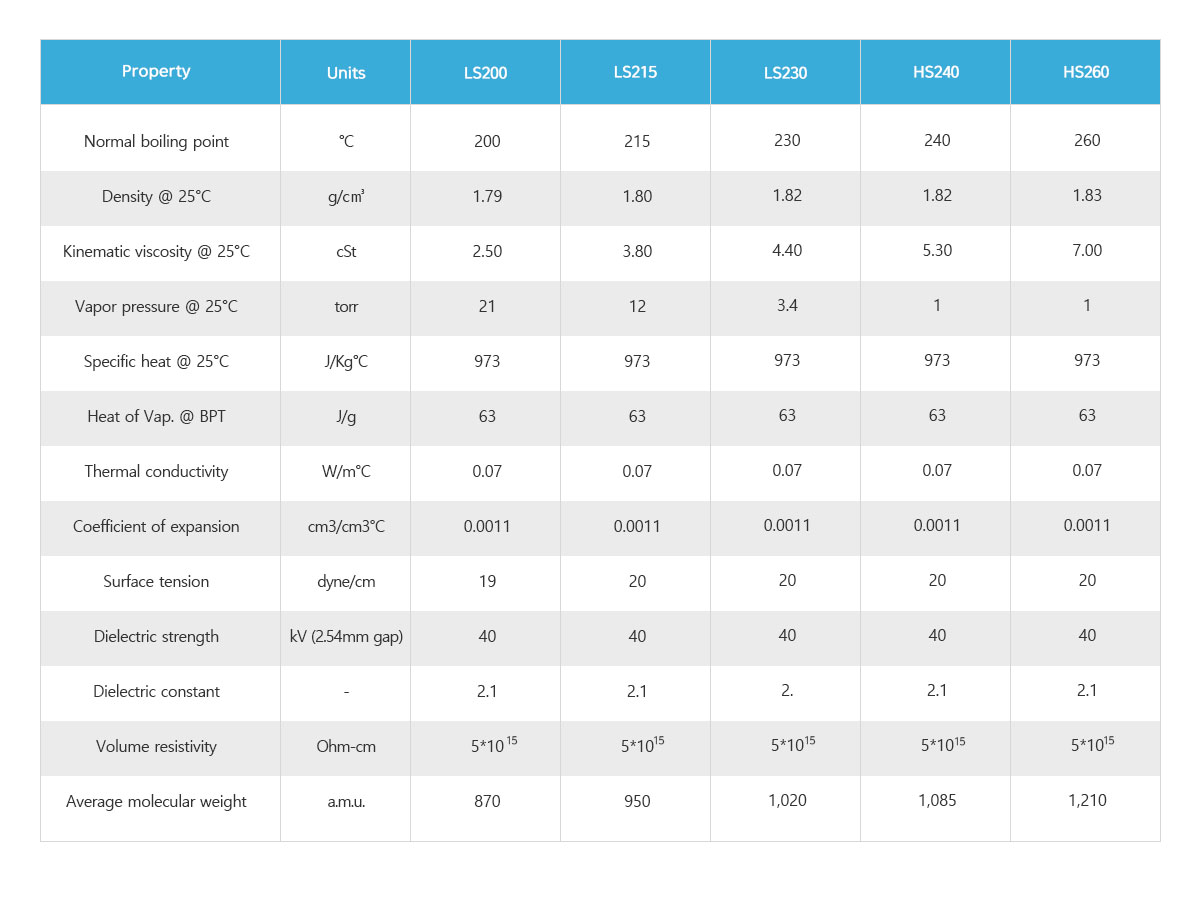

Vapor Phase Soldering Fluids

When the chips are packaged and tested, they must be assembled on mother boards. Vapor Phase Soldering (VPS) uses the latent heat of condensation of Galden® PFPE vapors in order to melt solder paste and hence to obtain reliable metal joints. Solder traditionally used ~ 60% of tin (Sn) and ~ 40% of lead (Pb).

Now alternative solder materials have been introduced; the most common replacements for lead are silver (Ag), Copper (Cu) and Bismuth (Bi). These alternative materials, however, bring a challenge: higher melting temperature. Traditional tin/lead solders melt at ~ 180°C while lead free solder melts at ~227°C. Soldering temperatures are, as well as heating issues, ongoing concerns for PCBs assemblers.

Galden® PFPE LS / HS is a line of fully fluorinated fluids specifically designed for the VPS process with the following properties:

•The narrow molecular weight distribution

•Very strong carbon-fluorine bond

•Flexible ether link

Galden® PFPE LS and HS fluids precise vapor temperature eliminates overheating, offering the widest temperature range to lead free solders up to 260°C and are RoHS compliant.Thermal Shock Testing

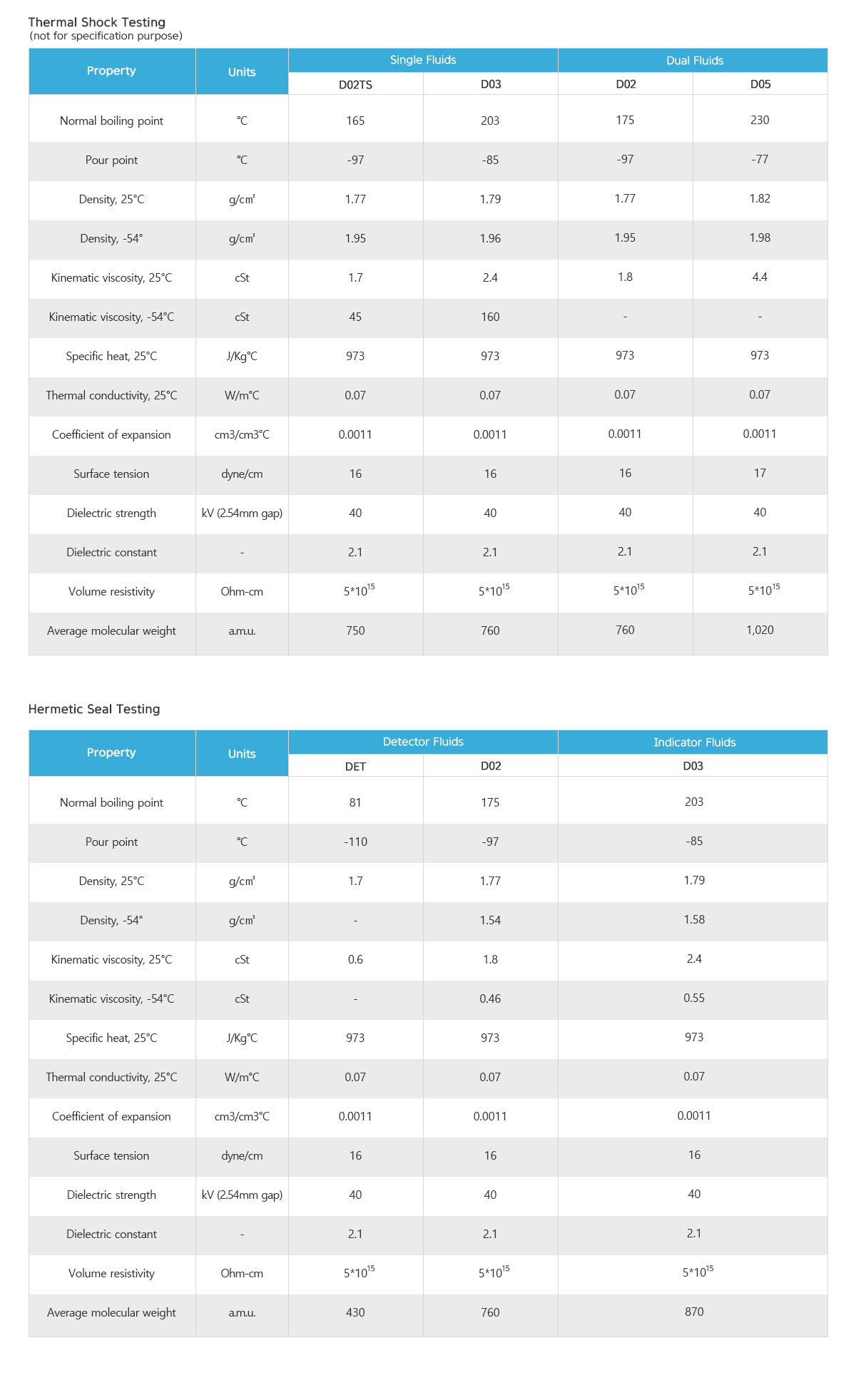

Thermal shock testing is performed to check the resistance of electronic devices to extreme changes in temperature. The test is carried out by alternately dipping the devices in liquids maintained at two different temperatures. For military applications the thermal shock test must be performed as specified in MIL STD 883 method 1011 or MIL STD 202 method 107.

Traditionally two different fluids can be used in the hot and cold bath but the Dual Fluid System presents several disadvantages. A Single Fluid System is possible with Galden® PFPE fluids because they can operate at very low as well as elevated temperatures. This Single Fluid System for both baths allows for a dramatic decrease in operating costs by:

•Limiting fluid consumption

•Reducing equipment downtime

•Eliminating cross contamination

•Reducing inventory to a single productGalden® PFPE D02TS and D03 are the single fluids which can successfully replace the need for a Dual Fluid System.

Galden® D02TS is proposed for all military applications; it meets the MIL STD 883 and MIL STD 202 while for all non-military applications Galden® PFPE D03 may be suitable.

Galden® PFPE Fluids for Thermal Shock Testing Conforming to MIL STD 883

Hermetic Seal Testing

Electronic devices must be completely sealed to avoid penetration by moisture and potential damage to the electrical response of the silicon chip. To guarantee the hermeticity of devices, a leak test procedure has been defined by MIL STD 883, MIL STD 750 and MIL STD 202.

Galden® PFPE fluids, being extremely inert and residue-free, are ideal and widely used as detector and indicator fluids in leak test procedures.

Galden® PFPE DET: detector fluid specifically designed for high reliability measures. Thanks to its perfect balance between low and high boilers components, it can easily detect large and small leaks. High boilers enter through large leaks and remain liquid until the test is performed while low boilers can easily penetrate into small leaks.

Galden® PFPE D02 and D03 are low consumption indicator fluids advantageously used as Indicator fluids respectively in military and non-military applications. They show an higher boiling point and a lower vapor pressure at test temperature

Galden® PFPE Fluids for Gross Leak Test Conforming to MIL STD

-

Semiconductor Test, Assembly & Packaging

-

Vapor Phase Soldering Fluids

Electronic devices must be completely sealed to avoid penetration by moisture and potential damage of the electrical response of the silicon chip. To guarantee the hermeticity of devices, a leak test procedure has been defined and ruled by MIL STD 883, MIL STD 750 and MIL STD 202.

Galden® PFPE fluids, extremely inert and residue free, are ideal and widely used as detector and indicator fluids in leak test procedures.

Galden® PFPE DET, the detector fluid specifically designed for high reliability methods thanks to its perfect balance between low and high boiler components, can easily detect large and small leaks. High boilers enter through large leaks and remain liquid until the test is performed while low boilers can easily penetrate into small leaks.

Galden® PFPE D02 and D03 are low consumption indicator fluids which can be advantageously used as indicator fluids respectively in military and non-military applications thanks to their higher boiling point and lower vapor pressure at test temperatures.

Thermal Shock Testing

Thermal shock testing is performed to check the resistance of electronic devices to extreme changes in temperature. The test is carried out by alternately dipping the devices in liquids maintained at two different temperatures. For military applications thermal shock test is performed as specified in MIL STD 883 method 1011 or MIL STD 202 method 107.

Traditionally two different fluids can be used in the hot and cold bath, but this practice presents several disadvantages.

Galden® PFPE fluids can operate at very low as well as elevated temperatures, and their Single Fluid System is an advantageous alternative to the Dual Fluid Solution.

A single fluid for both baths allows for a dramatic decrease in operating costs by decreasing fluid consumption, reducing equipment downtime, eliminating cross contamination and reducing inventory to a single product.

Galden® PFPE D02TS and D03 are the single fluids which can successfully replace a dual fluid system.

Galden® PFPE D02TS is proposed for all military applications; it meets MIL STD 883 and MIL STD 202 while for all non-military applications Galden® PFPE D03 may be suitable.

Hermetic Seal Testing

Electronic devices must be completely sealed to avoid penetration by moisture and potential damage to the electrical response of the silicon chip. To guarantee the hermeticity of devices, a leak test procedure has been defined by MIL STD 883, MIL STD 750 and MIL STD 202. Galden® PFPE fluids, being extremely inert and residue-free, are ideal and widely used as detector and indicator fluids in leak test procedures.

Galden® PFPE DET: detector fluid specifically designed for high reliability measures. Thanks to its perfect balance between low and high boilers components, it can easily detect large and small leaks. High boilers enter through large leaks and remain liquid until the test is performed while low boilers can easily penetrate into small leaks.

Galden® PFPE D02 and D03 are low consumption indicator fluids advantageously used as Indicator fluids respectively in military and non-military applications. They show an higher boiling point and a lower vapor pressure at test temperature

Galden® PFPE Fluids for Gross Leak Test Conforming to MIL STD

-

Electronic Reliability Testing

-

Non-reactivity, excellent dielectric properties, non-toxicity, non-flammability, and non-solvent features make Galden® D PFPE electronic fluids suitable for electronic reliability testing including thermal shock and hermetic seal testing.

Galden® PFPE Fluids for Gross Leak Test

-

Fuel Cells

-

Heat Transfer, Testing and Cooling

Galden® HT PFPE exhibits characteristics that make it the safest dielectric fluids for fuel cell:

•High thermal stability

•Chemical inertness

•No flash or fire point (FM 6930 listed)

-

Acid Spill Mitigation

-

A sulphuric acid spill is a critical event which requires prompt mitigation of dangerous vapor formation and release. The right mitigation media ought to be used to act effectively and eventually avoid adding further complications.

Galden® PFPE materials have excellent chemical inertness, are highly hydrophobic, have a high density while still lower than oleum, and are non flammable. In addition, Galden® PFPEs are completely immiscible with oleum.

Galden® PFPEs can be a suitable solution to create a continuous blanket material for oleum, sulphuric trioxide and sulphuric acid spill mitigation.

-

Solar Energy

-

Heat Transfer Fluids

Galden® PFPE fluids include a family of Ultra High Boilers (UHB), perfluoropolyethers specifically engineered for the high temperature applications typical of the PV and solar industries.

Key features

•Highest boiling point among all the fluorinated fluids

•Extremely wide operating temperature range (-70°C to +290°C)

•Excellent safety profile

•Outstanding chemical inertness

•No pressure build-up

•No fire and no explosion hazards

Typical applications

•Temperature control management of the manufacturing processes of crystalline and thin film PV solar cells Heat transfer fluids in the

•Solar Thermal and Concentrated Solar Power (CSP) industry

•Direct coolant in Hybrid PV/T and concentrated PV -

Solvent

-

Galden® SV PFPE are low molecular weight perfluoropolyether fluids used as carrier fluids for PFPE lubricants and for cleaning operations when:

•Applied to hot components

•Heated prior to application

•Pressure sprayed onto componentsVapor Pressure vs. Temperature