Applications

-

Aeronautics

-

Mechanical Components

Fomblin® PFPE-based fluorinated greases and lubricants possess a combination of exceptional properties such as:

•Chemical inertness

•Good lubricity

•Thermal stability

•Non-flammability

•Low volatility

•Low toxicityFomblin® PFPE lubricants have been a critical part of the space programs of both the United States (NASA) and the European Space Agency for over 25 years. For example, the Jet Propulsion Laboratory in Pasadena chose to use grease specially formulated by Castrol® using Solvay Fomblin® PFPE perfluorinated fluids for the highly successful Mars Pathfinder and its surface explorer, the Sojourner® Rover.

-

Automotive Air Induction Systems

-

Extend the life of your air induction system components with Fomblin® PFPE fluorinated lubricants. These high performance lubricants have exceptional properties, such as:

•Typical service temperature in automotive applications: from -40°C to 150°C.

•Fomblin® PFPE lubricants are characterized by their excellent properties at low temperature.

•The viscosity index of the Fomblin® PFPE oils can be higher than 300 and the friction at low temperature is very low.

•Fomblin® PFPE oils are compatible with metals, plastics and elastomers.

•Low evaporation weight loss which extends the service life of the lubricant and of the lubricated components.

•Fully fluorinated molecules are not mixable with water and have excellent behavior in terms of wash-out.

-

Automotive Cooling & Heating Systems

-

Fan & Radiator Lubrication

Fomblin® PFPE fluorinated fluids are high performance lubricants with exceptional properties such as:

•Low evaporation weight loss

•Low noise High viscosity index

•Anti-wear properties

•No carbonized residue formation

•Very long service life at high and low temperaturesSelf-lubricating bearings can be used in places where re-lubrication is difficult. The use of Fomblin® PFPE enables system designs without reservoirs, reducing the weight and the size of the components. Fomblin® PFPE is widely used as lubricants in sintered metal bearings for electric fans and radiators.

-

Automotive Fuel Systems

-

Fomblin® PFPE is a family of high performance fluorinated lubricants with exceptional properties such as:

•Compatibility with fuels Wide temperature service range

•Oustanding properties at low temperature

•Low evaporation weight loss, which extends the durability of the lubricant and of the lubricated components

•Non-flammable and safe

•Oxidation and thermal stability and resistant to most automotive solvents, oils, fluids and gases.Fomblin® PFPE is widely used as lubrication for mechanical and hydraulic components.

-

Automotive Interiors

-

Fomblin® PFPE fluids and Fomblin® PFPE-based greases are high performance perfluorinated polyethers lubricants having exceptional properties such low evaporation weight loss, low noise, high viscosity index, anti-wear properties, no carbonized residue formation, very long lubricating life at high and low temperatures.

Fomblin® PFPE fluids and Fomblin® PFPE-based greases are compatible with plastic, elastomer, metals and leather and used in applications such as headrests, sunroof systems, etc.

-

Automotive Mechanical & Structural Components

-

Fomblin® PFPE is the ideal lubrication solution for the automotive industry, meeting lubrication challenges by providing the best possible performance for demanding applications:

•Satisfying Extended Warranties - Components must be designed for lifetime lubrication

•Wide operating temperature range (from -85°C to +260°C ) to resist extreme environmental and engine temperatures

•Exceptional low temperature starting torque

•Compatibility with plastics, metals and elastomers commonly used in automotive design

•Elimination of NVH (Noise, Vibration, Harshness)

•Not affected by most automotive solvents, oils, fluids and gases

•Oxidation and thermal stability

-

Automotive Production Equipment

-

Fomblin® PFPE is the ideal lubrication solution for the automotive industry, meeting lubrication challenges by providing the best possible performance for demanding applications. It is used as neat oil, formulated into greases, or deposited on the part through suitable carriers.

•Oxidation and thermal stability

•Chemical resistance to most automotive solvents, oils, fluids and gases

•The broadest operating temperature range of any lubricant in its class, from -85°C to +290°C.

-

Electrical/Electronics

-

Contact Lubrication

A lubricant can extend the life of electrical switches and connectors. Some are designed for low electrical currents to send signals to relays and computers. Others are designed to carry high electrical loads to starters, headlights and turn signals. More and more switches are expected to do both and to perform across a wide temperature range.

Fomblin® PFPE lubricants are characterized by their excellent electrical properties and extremely wide operating temperature range. They are used to lubricate automotive connectors where the low temperature (-40°C) specifications are especially challenging.

Fomblin® PFPE oils have low electrical resistance in thin films without affecting the resistance between adjacent conductors or components.

Vacuum Pump Lubrication

Fomblin® PFPE fluorinated fluids are:

•Thermally stable

•Chemically inert

•Non-flammable

•Non-toxic

They are compatible with:

•Metals

•Hydrogenated polymers

•Oxygen

•Aggressive gases, even at very high temperatures.

They possess:

•Low vapor pressure

•Good dielectrical properties.When critical applications have to be addressed where aggressive chemical environments, high temperatures or wide working temperature ranges are involved, they represent the lubricants of choice. Fomblin® PFPE Y LVAC and Y HVAC grades are ideal for use in vacuum pumps as sealing and working fluids especially in those systems exposed to aggressive gases. Fomblin® PFPE Y HVAC combines narrow molecular weight range and controlled viscosity with an extremely low vapor pressure.

Chemical inertness, thermal stability above 290°C and the potential to provide anti-rust and anti-wear additivation make the Fomblin® VAC product line ideal for lubrication of vacuum pumps in harsh environments such as semiconductor processing.

Magnetic Recording Media Lubrication

Fomblin® PFPE Z derivatives are well know lubricants for the Magnetic Recording Media industry. They are used as top lubricant on the HD drive surface to prevent damaged on the disk surface.

-

Food Service Equipment

-

Bakery Oven Lubrication

Fomblin® PFPE-based fluorinated greases are ideally suited for use as an oven chain and bearing lubricant, especially for high temperature applications. They offer outstanding properties:

•Stable performance in extreme temperatures

•Reduced friction and wear while extending equipment life in severe duty applications

•Approved and registered by NSF International in the H1 category

•Non-toxic, no decomposition and no carbon residue

•Resistant to acidic or caustic cleaners, steam, moisture

•Increased ease of maintenance and reduced service time with less risk of downtime.

-

Oil & Gas Downhole

-

HPHT Hydraulic Fluids

In the Oil & Gas industry there is an increasing need for hydraulic fluids able to withstand extreme temperatures up to 260°C and high pressures (30,000 psi). The conventional hydraulic fluids start degrading at 220°C, while Fomblin® PFPE oils are stable up to 290°C.

Fomblin® PFPE key properties:

•Temperature resistance (up to 290°C)

•Resistance in very aggressive environments

•Dielectric properties make them suitable to be used in contact with electronic equipmentSolvay offers a portfolio of anti-wear and anti-rust additives to be used in combination with the Fomblin® PFPE oils.

-

Semiconductor Manufacturing

-

Wafer Processing

Fomblin® PFPE lubricants are ideal for use as vacuum pump oils in wafer manufacturing processing such as dry etching and CVD.

Frequently Asked Questions - Y and M/Z Grades

-

What is Fomblin® PFPE?

-

The trade name Fomblin® PFPE identifies a family of synthetic lubricants entirely composed of carbon, oxygen and fluorine, belonging to the class of perfluoropolyethers. They are produced by Solvay Specialty Polymers through a proprietary and versatile technology: the low temperature reaction of oxygen with perfluorinated olefins activated by UV light. This platform allows to obtain different structures in a wide range of molecular weights. Key properties such as viscosity and vapor pressure can therefore be tailored to the target application. They are clear, colorless and odorless oils that remain liquid in a very wide range of temperatures, spanning from –100 °C up to 300 °C. Fomblin® PFPEs are thermally stable, chemically inert, and compatible with metals, hydrogenated polymers, oxygen and aggressive gases even at very high temperatures.

They are not flammable and non-toxic. They have low vapor pressure, good dielectrical properties, low refractive index and low surface tension.

When critical applications have to be addressed where aggressive chemical environment, high temperatures or wide working-temperature ranges are involved they represent the lubricants of choice.

Fomblin® PFPE oils can be thickened with polytetrafluoroethylene (PTFE) to give white and homogeneous lubricating greases of different consistency.

-

What is the Difference Between Fomblin® Y and Fomblin® M/Z?

-

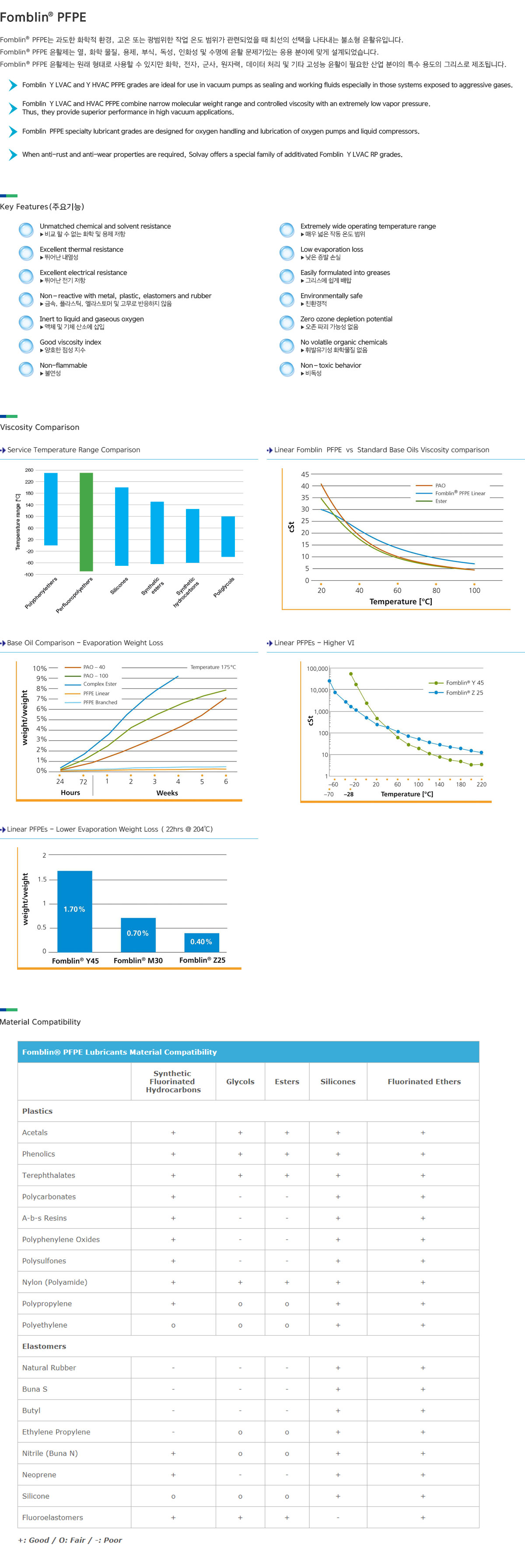

Fomblin® Y and Fomblin® M/Z perfluoropolyether fluids are produced starting from different monomers, hexafluoropropene and tetrafluoroethylene respectively, and for this reason they have different chemical structures:

Fomblin® Y

Fomblin® M/Z

Fomblin® M/Z oils have excellent viscosity indexes, very low evaporative losses, excellent low-temperatures properties and good thermal stability.Fomblin® Y oils are characterized by excellent thermal stability, good viscosity index, good low-temperature properties and low evaporative losses.

-

What Makes Fomblin® PFPE Lubricants Better?

-

The following combination of properties and characteristics makes for sure Fomblin® PFPE the right product for your application:

•Excellent chemical and solvent resistance

•Excellent thermal resistance

•Excellent electrical resistance

•Non-reactive with metal, plastic, elastomers and rubber

•Inert to liquid and gaseous oxygen

•Excellent radiation hardness

•From good to outstanding (> 300) viscosity index depending on the grade

•Non-flammable

•Extremely wide operating temperature

•From low to extremely low evaporation loss depending on the grade

•Excellent properties at low temperatures, starting torque for example, depending on the grade

•Excellent water washout properties

•Good low and high temperature wear properties

•Easily formulated into greases

•Environmentally safe

•Zero ozone depletion potential

•No volatile organic chemicals

•Non-toxic

-

What are the Applications where Fomblin® PFPE Lubricants are Top Performers?

-

Fomblin® PFPE lubricants and their formulations into greases are successfully employed in all the industries in need of high performance lubrication like chemical, electronic, military, nuclear and data processing.

Examples of uses of Fomblin® PFPE lubricants include:

•Tenter frames in the textile industry

•Deep space rocket nozzle lubrication

•Missile catapult system lubrication

•Sintered metal bearings requiring exceptional operating life

•Anti-lock braking systems

•Oxygen and chlorine valves and pumping systems

•Sealing fluids for vacuum pumps

•Gold contact surface lubrication

•Nuclear industry lubricants

•Instrument lubricants

•Lifetime sealed, maintenance-free bearings

•Lubricants for gasoline tank floats

•Bearings exposed to high temperatures, moisture and aggressive chemicals

-

Can Fomblin® PFPE be Used in a Clean Room Environment?

-

The complete spectrum of vacuum needs, low/medium/high, is covered by a selection of Fomblin® PFPE oils’ grades. More in detail, Fomblin® Y LVAC are grades designed for vacuum pumps as sealing and working fluids in the presence of aggressive gases. Fomblin® HVAC are the products of choice for high vacuum applications (10–3 mbar to 10–7 mbar) since they combine narrow molecular weight distribution and controlled viscosity with an extremely low vapor pressure.

-

Can Fomblin® PFPE be Used in Medical Applications?

-

Fomblin® PFPE products have not been approved for medical applications involving permanent or temporary implantation in the human body or permanent or temporary contact with internal body fluids or tissues.

-

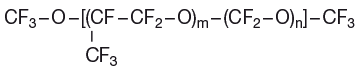

Is Fomblin® PFPE Pressure Sensitive?

-

The performance of Fomblin® PFPE lubricants is unaffected by pressure. Their viscosity increases under pressure and they compress slightly. The viscosity of Fomblin® Y shows a more pronounced dependence on pressure compared to Fomblin® Z. This is due to the different chemical structure and in particular to the presence of the bulky – CF3 pendant group in the chain of Fomblin® Y. The figure below shows variation of the viscosity with pressure, measured at 30 °C in the range 3 – 10 MPa for a Fomblin® Y and a Fomblin® Z having comparable viscosity of 250 cSt at 20 °C.

Fomblin® PFPE viscosity vs. pressure chart

-

What is the Recommended Temperature Range for Use of Fomblin® PFPE?

-

Fomblin® PFPE oils can be used from – 90 °C up to 290 °C depending on the grade. Fomblin® PFPE doesn’t burn or carbonize to form tarry deposits thus avoiding a typical cause of equipments failure at very high temperature. The only modification you may observe is a light evaporation of the oil. Our wide selection of products allows minimizing this effect by matching application requirements and oil profile. Fomblin® PFPE oils are designed to provide lubrication also when heating and vacuum are combined, conditions under which conventional oils would be vaporized leading to contact metal counterfaces seizure.

-

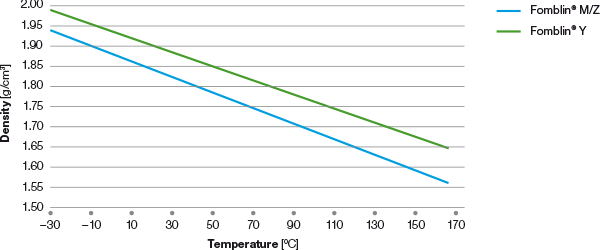

What is the Density of Fomblin® PFPE?

-

The density of Fomblin® PFPE oils is approximately twice that of standard lubricants; it is comprised between 1.8 and 1.9 kg/liter depending on the grade. This has to be taken into account when filling bearings by weight. The typical dependence of density on temperature for two grades of Fomblin® Y and Fomblin® M having similar viscosities at 20 °C is shown in the figure below.

Fomblin® PFPE density vs. temperature chart, ASTM D4052

-

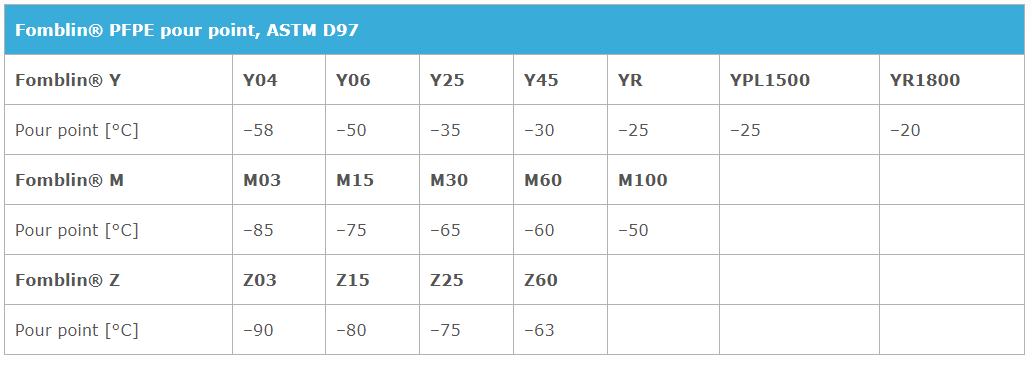

What is the Pour Point of Fomblin® PFPE?

-

Fomblin® PFPE oils are able to flow down to extremely low temperatures, having pour points as low as – 90 °C in the case of Fomblin® M/Z. Typical values are shown in the table below.

-

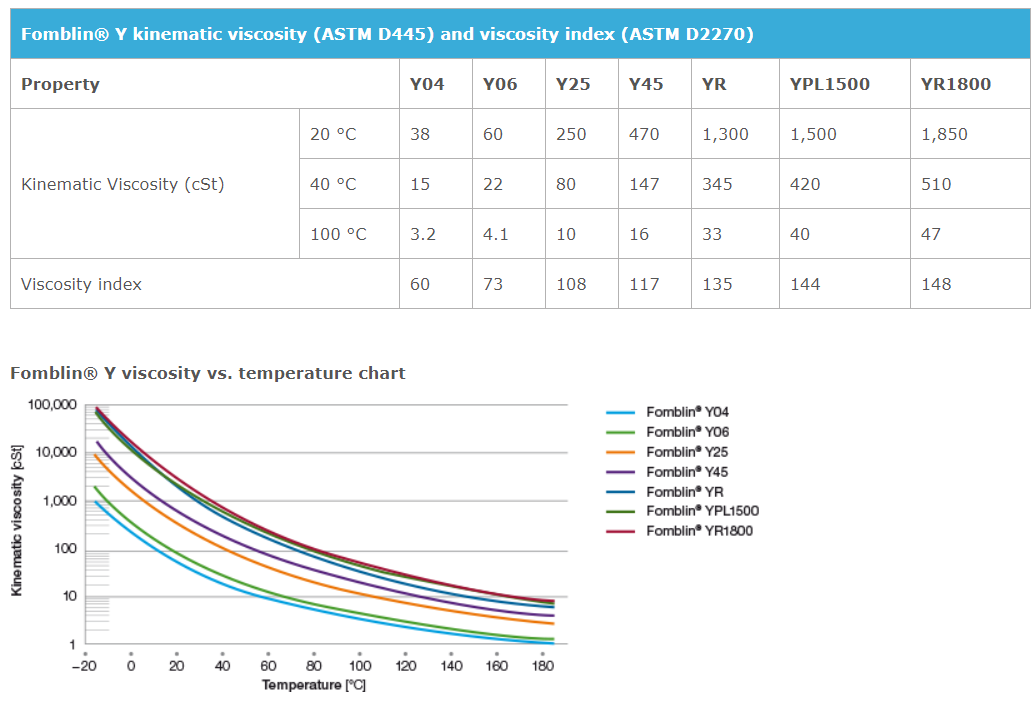

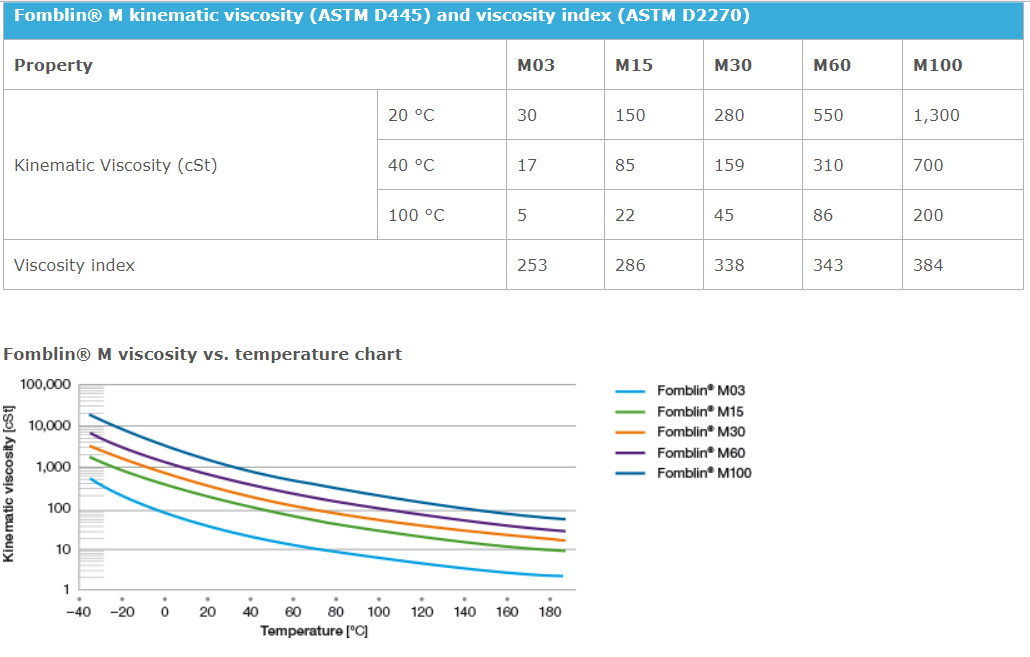

What is the Viscosity Range and Viscosity Index of Fomblin® PFPE?

-

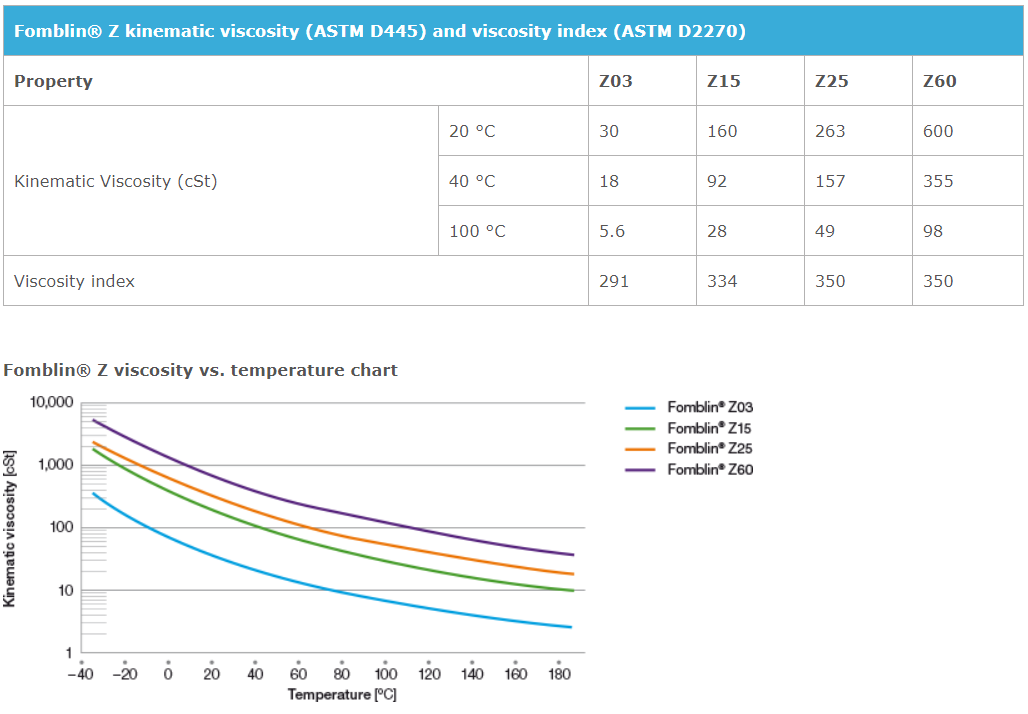

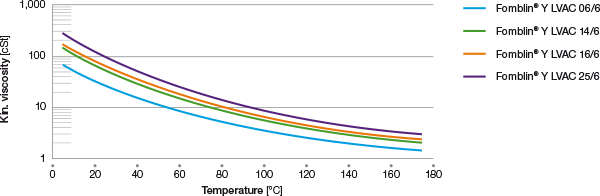

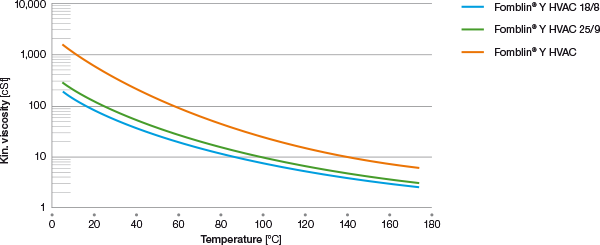

Fomblin® PFPE lubricants cover a wide viscosity range and are characterized by very good Viscosity Index (VI), varying from 60 to 350 depending on the grade. High VI means slow change of viscosity with temperature and, consequently, a wider operating temperature range. The effective viscosity of a lubricant in a bearing may be different from the quoted viscosity measured by a standard test method. This difference depends on the actual shear rate in the bearing that can be higher compared to conditions typical of test methods. Fomblin® PFPE oils display Newtonian behavior, e.g. their viscosity remains constant up to shear rate as high as 106 s–1.Typical values are reported in tables 2 – 4 for Fomblin® Y, M and Z. Figures 3 – 5 show viscosity temperature relationship.

-

Is Fomblin® PFPE Flammable?

-

No. Fomblin® PFPE is not flammable. It doesn’t have a flash, fire or autoignition point. Fomblin® PFPE fluids are Factory Mutual Underwriters Approved.

-

Is Fomblin® PFPE Radiation Resistant?

-

Fomblin® PFPE has a good resistance to radiations. It can be used for the lubrication of gears in UF6 ultracentrifuges.

-

Does Fomblin® PFPE Oxidize?

-

The structure of Fomblin® PFPE, thanks to the presence of fluorine, is highly stable and inert. For this reason Fomblin® PFPE does not oxidize unlike hydrocarbons and other synthetic lubricants.

-

Is Fomblin® PFPE Hazardous?

-

No. Fomblin® PFPE are very safe fluids:

•No flash or fire point

•No explosion hazard

•No toxicity

•No autoignition point

•Thermal, oxidative and chemical stability

•Shelf life over 20 yearsFomblin® PFPE fluids are chemically inert and thermally stable up to 300 °C. Some of the decomposition products are potentially dangerous. Fomblin® PFPE do not react with chemicals and refrigerants and do not get oxidized.

-

What are the Electric Properties of Fomblin® PFPE?

-

Fomblin® PFPE fluids are dielectric materials. They have low dielectric constant (typical value 2) and high volume resistivity (typical value 1·1015 ohm·cm).

-

Is Fomblin® PFPE Compatible with Various Materials?

-

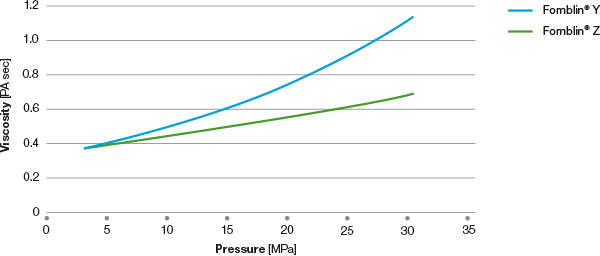

Fomblin® PFPE oils are compatible with all types of polymers, plastomers and elastomers. Nitrile, butyl, polyfluorosiloxane, EPDM rubber don’t show any sign of swelling or mechanical or physical alteration after prolonged contact with Fomblin® PFPE. Melamine, phenolic, polyoxymethylene, and polyolefin resins can be used in combination with Fomblin® PFPE up to their limit of operational range. Fomblin® PFPE lubricants are compatible with glass, ceramics and metals. They can be used with water, oils vapor and in general with all organic compounds and not-highly-fluorinated solvents without being removed, dissolved or modified in any way. Compatibility data of Fomblin® PFPE lubricants are shown in the tables below. Specific compatibility tests according to standard methods can be performed upon request.

Internal method; unchanged means no change in acid number and viscosity change ± 2 %

ASTM D471, 70 °C, 166 hrs, on grades having viscosity of 250 cSt at 20 °C

-

Does Fomblin® PFPE Have Antirust Properties?

-

Perfluoropolyethers are characterized by somewhat low anti-rust properties. Solvay Specialty Polymers has developed a family of proprietary soluble anti-rust additives. These additives, Fomblin® DA305 and Fomblin® DA306/VAC, comes from the same technological platform as Fomblin® PFPE oils. They present functional groups which allow them to interact with the surfaces establishing durable bonds and consequently improving surface protection. Fomblin® DA305 is specially designed to work with Fomblin® PFPE based greases, while Fomblin® DA306/VAC has been designed for oils. The availability of additivated Fomblin® PFPE oils widens the range of applications for perfluorinated lubricants in fields requiring improved anti-rust properties.

-

How Do I Select a Grade for a Particular Application?

-

Our technical service team is at your disposition to help you select the right Fomblin® PFPE product for your application. Don’t overlook basic details that can have a significant impact on the resulting lubricant’s performance. You should provide us with as much information as possible to help us identifying the lubricant best suited to your needs.

The key requirement for selecting the proper lubricant is the base oil viscosity. In order to select the appropriate viscosity, we need to gather information about your application, including:

•Operating speed (variable or fixed)

•Specific type of friction (e. g., sliding or rolling)

•Load and the environmental conditions

•Industry standardsIf your equipment is lubricated for life, synthetic oils are recommended for their many benefits, including:

•Low/high temperature viscosity performance combined with decreased evaporative loss

•Reduced friction and reduced wear

•Improved efficiency and chemical stability

•Resistance to oil sludge problems and extended drain intervals

-

Is Fomblin® PFPE Food Grade Approved?

-

Fomblin® M03, M15, M30, M60, Fomblin® Y04, Y06, Y25, Y45, YR, YR1800, Y LVAC 25/6 are all approved with the intended use described below:

•H1: General, incidental contact

•H2: General, no contact

•HX-1: Ingredients for use in H1 lubricants, incidental contact

•HX-2: Ingredients for use in H2 lubricants, no contact

Fomblin® M15/RP, M30/RP, M60/RP, Fomblinv Y25/RP, YR1800/RP are all approved with the intended use described below:

•H1: General, incidental contact

•H2: General, no contact

-

Is Fomblin® PFPE Factory Mutual Approved?

-

Fomblin® PFPE lubricants are approved according to FM 6930 standard for flammability classification of industrial fluids. This standard states the flammability classification rating for industrial fluids intended for, but not limited to, lubricants, hydraulic power transmission, turbine governor control, transfer insulation and cooling.

-

Is Fomblin® PFPE Safe for Oxygen Service?

-

Yes. Bundesanstalt fur Materialprüfung, Berlin (BAM) has approved the use of Fomblin® PFPE fluids in the presence of oxygen. Additionally, the National Aeronautics and Space Administration (NASA) and the Naval Ship Engineering Center of the US Navy have both approved the use of Fomblin® PFPE fluids in liquid oxygen applications. Fomblin® LC grades are special fluids for oxygen handling and lubrication of oxygen pumps and compressors. Fomblin® LOX are special fluids tailored for handling oxygen when a low vapor pressure is required. Different grades having different viscosity/temperature relationships are available. Temperature and pressure limits of oxygen with Fomblin® PFPE are available upon request.

Frequently Asked Questions - VAC Grades

-

What is the Difference Between Fomblin® PFPE Oil and Fomblin® VAC?

-

Fomblin® VAC fluids have been specially developed in order to combine narrow molecular weight range and controlled viscosity with an extremely low vapor pressure. Thus, they provide superior performance in high vacuum applications, especially systems exposed to aggressive gases. Solvay Specialty Polymers is able to provide these grades due to its edging technology where distillation step makes us able to design tailor-made products according customer requirements.

-

What is the Difference Between Fomblin® Y LVAC and Fomblin® Y HVAC?

-

Fomblin® Y LVAC grades are ideal for use in vacuum pumps as sealing and working fluids especially in those systems exposed to aggressive gases.

Fomblin® Y HVAC combines narrow molecular weight range and controlled viscosity with an extremely low vapor pressure. Thus, they provide superior performance in high vacuum applications as working fluid specially for diffusion pumps.

-

Based on My Vacuum Pump, which Fomblin® VAC Grade Should I Use?

-

-

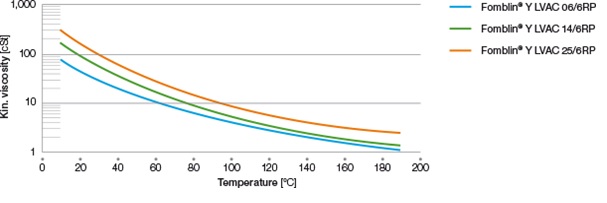

What is the Kinematic Viscosity Behavior vs. Temp. of Fomblin® VAC Fluids?

-

Fomblin® Y LVAC viscosity vs. temperature chart

Fomblin® Y HVAC viscosity vs. temperature chart

-

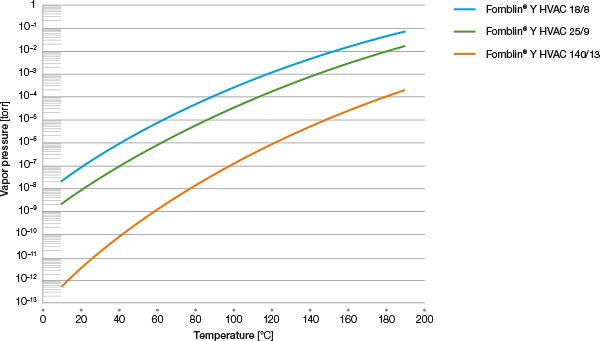

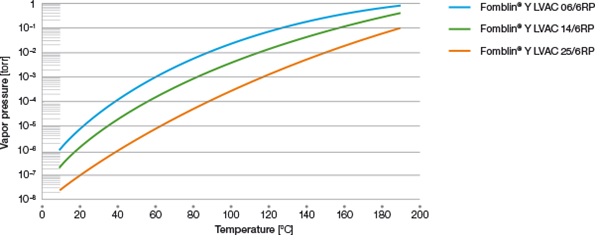

What is the Vapor Pressure Behavior vs. Temperature of Fomblin® VAC Fluids?

-

Fomblin® Y LVAC vapor pressure vs. temperature chart

Fomblin® Y HVAC vapor pressure vs. temperature chart

-

Are Fomblin® VAC Additivated Grades Commercial?

-

Rust Preventive formulation (LVAC RP) was studied to reduce or prevent rusting when huge amount of water vapors has to be pumped or when metal surfaces of the pump are exposed to moisture. An optimum concentration of additive in Fomblin® Y LVAC grades was studied to provide protection against rust and at the same time to guarantee the physical properties and the vacuum performance of the grade.

Anti-rust property evaluation

•Fog chamber (method ASTM B117)

•Conditions: temperature = 45 °C, humidity = 90 %

Rating

0 – No corrosion

1 – Not more than three small spots of corrosion

2 – Small areas of corrosion covering up to 1 % of the surface

3 – Small areas of corrosion covering from 1 % to 5 % of the surface

4 – Small areas of corrosion covering from 6 % to 10 % of the surface

5 – Small areas of corrosion covering more than 10 % of the surfaceFomblin® PFPE anti-rust additivated grades maintain the same viscosity and vapor pressure behavior than not additivated ones. As the following charts show:

Fomblin® Y LVAC RP – viscosity vs. temperature chart

Fomblin® Y LVAC RP – vapor pressure vs. temperature chart

-

Are Fomblin® Y LVAC Fluids Food Grade Approved?

-

Fomblin® Y LVAC 25/6 is NSF approved with the intended use described below:

•H1: General, incidental contact

•H2: General, no contact

•HX-1: Ingredients for use in H1 lubricants, incidental contact

•HX-2: Ingredients for use in H1 lubricants, no contact